WASINO G 100M | 480

High-quality Workpieces Generated by Super-high-precision Machining

Max. workpiece diameter

11 in.

285 mm

Max. workpiece length

11 in.

280 mm

Max. bar capacity diameter

1 in.

38 mm

Max. X-axis stroke

19 in.

480 mm

Max. Z-axis stroke

11 in.

285 mm

Control & software alternatives

Fanuc

Highlights

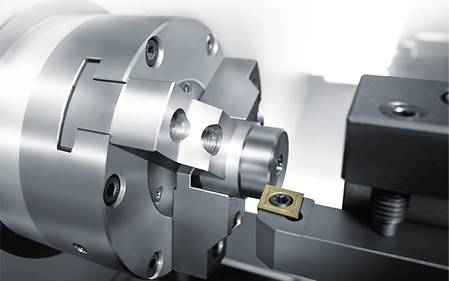

Super-high precision

- Maintaining stable dimensional accuracy even over long-term operation thanks to the rigid bed with low center of gravity

- Thermal displacement (at cold start): ø 2.0 μm <G 100 | 300> Circularity: 0.5 μm

- Adoption of a pre-tension structure suppresses thermal displacement and realizes high positioning accuracy

High rigidity

- Adoption of symmetrical structure with respect to the spindle center, unique to a flat tooling turning center

- Cast iron construction with superior damping performance and high resistance to chatter

- Induction-hardened horizontal slideways integrated on the bed suppress thermal displacement

Expandability

- Versatile system variations to accommodate diverse production needs

- A wealth of highly practical applications and peripheral devices available

Power-saving

- Environmental burden reduced by using energy-efficient components

Application Examples

Automation

Open up the possibilities of automation

Increase productivity and quality, and operate 24/7. Our solutions offer extended machine uptime and support sustainability. Optimize your processes with our innovative automation solutions!

Control & Software

Experience the speed of digital transformation (DX)

Revolutionize your operations, unlock new opportunities, increase efficiency and promote sustainability by reducing power consumption – while gaining a strong competitive advantage.