CLX 750

Main drive with 2.000 Nm for heavy cutting of workpiece up to 600 kg – with direct measuring system (X or X/Y) in standard

Max. workpiece diameter

28 in.

700 mm

Max. workpiece length

51 in.

1,300 mm

Max. bar capacity diameter

5 in.

127 mm

Max. X-axis stroke

17 in.

435 mm

Max. Y-axis stroke

6 in.

160 mm

Max. Z-axis stroke

51 in.

1,300 mm

Control & software alternatives

SIEMENS

Fanuc

Highlights

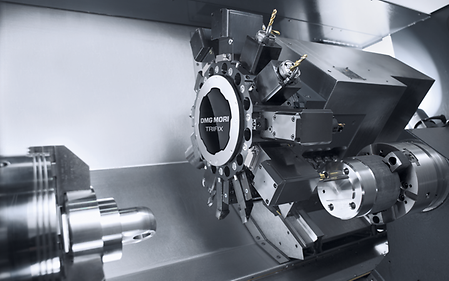

Complete machining of complex parts thanks to counter spindle and Y-axis

- Highly dynamic spindle drive 48 kW (40% DC) and 2000 Nm (40% DC) with max. speed up to 2.000 rpm

- Counter spindle as integrated motor spindle ISM 76 with power 32 kW (40% DC), 360 Nm (40% DC) and max. speed up to 4.000 rpm with the possibility for rear-face machining.

- Y axis with travel range ± 80 mm for superior milling operations, i.e. for complete lateral surface machining

NEW: Highest level of precision and accuracy thanks to direct measuring system in standard

- enhanced accuracy of the machining process and improved process stability

- well-proven solution from MAGNESCALE for highest accuracy and precision

More efficiency for machining of long workpieces

- Bar capacity ø127 mm in standard

- Optional steady rest up to size RX5 (Ø430 mm)

- Optional automation interface according to DMG MORI standard

Compact design with large working area for the machining of workpieces up to 600 kg!

- Machining of parts with diameter up to ø700 mm

- Travel in Z axis: 1300 mm

- Small and compact footprint of 8,9 m²

NEW: IoTconnector for digitized and connected production processes in standard!

- DMG MORI NETservice and MESSENGER preinstalled

- Quick and easy installation in the control cabinet via LAN cable

- Specially preconfigured for your machine prior to delivery via the machine’s serial number

- Standard interfaces allow fast and reliable data exchange

- Integrated firewall with automatic updates guarantees maximum protection for your machine

3D controls with the unique 19" SLIMline touch control panel - with SIEMENS or FANUC.

- Create your own individual solution!

- 19" DMG MORI SLIMline multi-touch control panel and SIEMENS for intuitive use and easy operation

- 19" DMG MORI SLIMline touch control panel and FANUC for 3D simulation with easy contour verification

- DMG MORI SMARTkey: Personalized with 8 GB additional storage

Application Examples

Automation

Open up the possibilities of automation

Increase productivity and quality, and operate 24/7. Our solutions offer extended machine uptime and support sustainability. Optimize your processes with our innovative automation solutions!