ULTRASONIC 20 linear 3rd Generation

ULTRASONIC 20 linear - the most precise 5-axis simultaneous machine within DMG MORI

Max. X-axis stroke

9 in.

220 mm

Max. Y-axis stroke

15 in.

370 mm

Max. Z-axis stroke

11 in.

290 mm

Max. workpiece length

12 in.

302 mm

Max. workpiece width

9 in.

220 mm

Max. workpiece diameter

9 in.

220 mm

Max. workpiece height

11 in.

283 mm

Max. workpiece weight

33 lbs.

15 kg

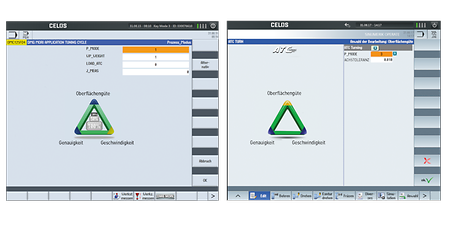

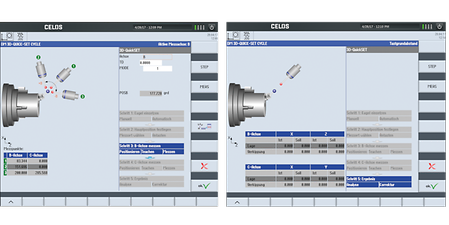

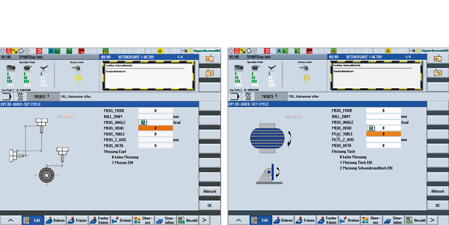

Control & software alternatives

SIEMENS

Highlights

ULTRASONIC 20 linear - Precise, compact and dynamic!

- Maximum dynamics and acceleration (up to 1,2 g), thanks to wear-free linear drives

- New FEM-optimized cast bed for maximal high long-term stability of the machine

- Finely tuned and highly sensitive temperature management

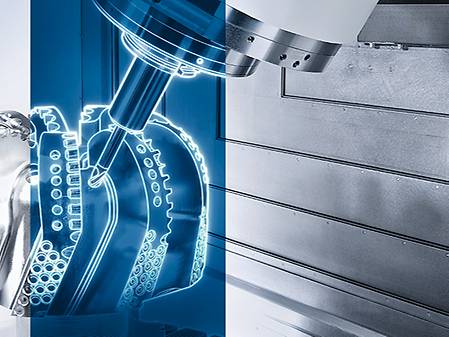

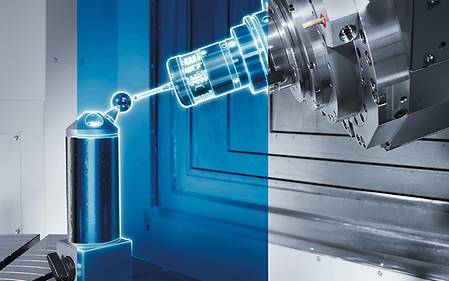

ULTRASONIC technology integration - reduced process forces for higher productivity

- Technology integration via HSK-E32 interface for ultrasonic superimposition of tool rotation with amplitudes of up to 15 µm

- Process forces reduced by up to 50% thanks to ULTRASONIC: higher feed rates, improved surface finishes down to Ra < 0.1 µm, longer tool service life depending on requirements

- Stable process window during machining for maximum reproducibility and consistent machining results.

- Ensuring the ULTRASONIC advantages even with non-optimal tools.

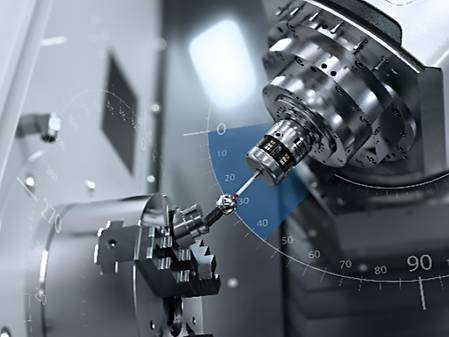

5-sided complete simulatnious machining of workpieces up to Ø 220 x 283 mm

- More travel path and larger working area:

- X = 220 mm

- Y = 370 mm

- Z = 290 mm

- Large swivel range of the A-axis: +130° to -93° with max. 15 kg table load

- Standard: 150 rpm in the C-axis

- Optional: 1,500 rpm in the C-axis

High-performance spindles for optimum machining performance with max. 60,000 rpm

- High frequency spindels: HSK-32: 42.000 rpm (60.000 rpm)

- Optionally with HSK-32 spindle with max. 60.000 rpm

Application Examples

Automation

Standard automation and customized solutions in the VERTICO design

Automation is a key element of digital production. Every DMG MORI machine can be upgraded with standard automation or with a customized automation solution for flexible manufacturing systems: